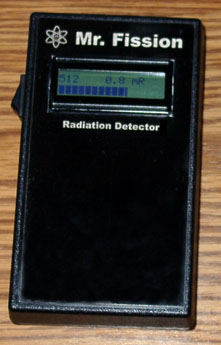

Mr. Fission

This is pretty much a one-off project I did. I'm hoping to document it and make it something a little more reproducible in the future.

A couple of years ago I picked up an old Civil Defense Geiger counter to play with. The unit was at least a decade older than me, and after a week or two it just died. I poked around a bit and finally decided that the corona discharge voltage regulator tube must have gone out.

So rather than try to find a replacement for a part that was obsolete when I was still in diapers, I did what any self-respecting hardware hacker would do. I junked it for parts and built a new one. High voltage design isn't really my thing, so I looked around a bit and found the Bargraph Geiger Counter by Russell Clift, AB7IF. The bargraph display wasn't what I wanted, but the high voltage power supply served as a starting point.

My design is based around a Motorola MC68HC908KX8 microcontroller. The MCU takes the place of the inverter's oscillator using one of its timer outputs (which incidentally makes it possible to tune the voltage output in software), and the detector stage converts pulses from the Geiger-Mueller tube into interrupt request signals. The processor counts the pulses and uses a 16x2 LCD display to show a 1-minute count average, a milliRoentgens/hr reading, and a bargraph display with a 3-second integration period.

Of course, this can all be changed in software. I'm planning to revise the design and add an RS-232 port that'll provide either raw counts for radiation monitoring or random numbers for cryptography use or anything that needs really, really random numbers.

Unfortunately the original design uses a couple of obsolete or otherwise hard-to-obtain parts. The new version I'm testing uses a cheap, readily available inverter transformer intended to drive CCFL lamps. The transistor that drives the primary winding needs to be replaced with a modern equivalent. The high voltage capacitors are one of the more expensive parts in the device, and I'm testing cheaper ceramic replacements for the metalized polypropylene ones it currently uses. Electronic Goldmine currently carries suitable capacitors, LCD displays, and transformers. Using their parts it should be possible to reduce the cost of the project to $20 or so, not counting the GM tube.

I'll post more information, including schematics, when I get a chance. Until then, if you're interested in the project, you can contact me at the address below.

![]()